While every Purchase Green customer has unique goals for their artificial grass installation project, pretty much every customer shares at least one thing in common – they want their grass to be installed properly. Whether it’s a DIY project or a professional job, a proper artificial grass installation is built on a solid foundation. And the best way to build that foundation is with a vibratory plate compactor.

See a vibratory plate compactor in action!

Good vibrations!

When installing artificial grass over native soil, Purchase Green recommends excavating the soil to a depth of about 3 to 5 inches. Why? So you can fill that excavated area with crushed rocks! Now, you may be wondering what crushed rocks have to do with artificial grass. You see, we never recommend installing artificial grass directly atop native soil because native soil contracts and expands with the seasons. When it’s hot and dry the soil shrinks. When it’s wet out the soil grows. And if you’ve attached your grass to that soil it’s going to end up with mounds, dips, wrinkles…it’s not going to look good. And it’s not going to perform well either. But, if you have built a sub-base out from that crushed rock, then your artificial grass can be installed over a base that won’t expand and contract – thus ensuring your grass looks great no matter what the weather. To get that beautiful, smooth and unmovable sub-base, you need to use a vibratory plate compactor.

Some things to keep in mind when using a vibratory plate compactor. First, they’re pretty heavy! So be sure to have help whenever you’re loading or loading them from a truck, trailer, etc. Newer models, like the ones we carry, have folding wheels that make moving the machines much easier. Second, aim for a 90-95% rate of compaction. Basically, if your sub-base material is level with the existing hardscape/landscape that surrounds the project area, you want to achieve a compaction that results in a sub-base surface that is ¾” lower than the surroundings. Third, you’ll need to go over the project site with the compactor several times. In between compacting sessions, spray the sub-base with a hose – this helps remove any voids or air pockets.

You may encounter areas of your project the plate compactor can’t quite reach. In those situations, use a hand tamper instead.

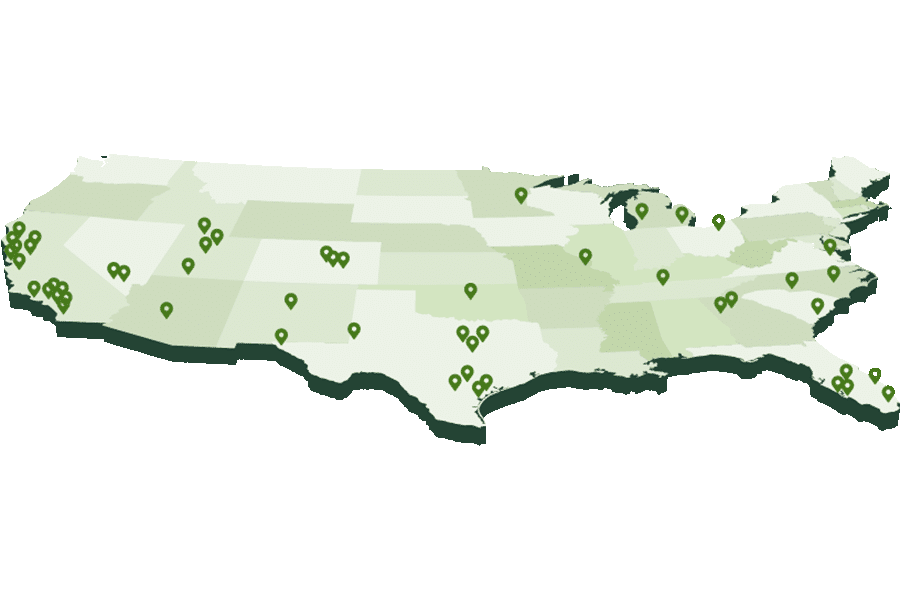

So where does one get a vibratory plate compactor? Well, we sell them in our stores (our is a powered by a Briggs & Stratton 208cc XR Professional engine that produces 6.5 hp!), which is fantastic if you’re a contractor. But if you’re a DIYer doing a single, small project you probably don’t need to buy a vibratory plate compactor. Check around your city or neighboring cities for a tool rental business. Any shop that rents landscape equipment like ditch diggers, skid steers, small tractors and the like probably has a vibratory plate compactor for rent, too.

If you have any questions about vibratory plate compactors or anything else related to artificial grass, give us a call! Happy compacting!